In the aerospace and defense industries, maintaining optimal operating conditions and preventing overheating in engines is of paramount importance. This is where engine Surface Air-Cooled Oil Coolers, SACOC plays a vital role. Engine surface coolers are meticulously designed thermal solutions that effectively dissipate heat, ensuring peak performance and reliability for engines in demanding aerospace and defense applications.

By dissipating heat effectively, engine SACOCs contribute to enhanced engine performance, improved fuel efficiency, and extended service life. These coolers conform to the shape of the engine cowlings/ducts and range in lengths to span the circumference of small business jets to large commercial engines. They help prevent premature wear and damage to engine components, reducing the risk of costly repairs and downtime. These coolers are essential for the safe and reliable operation of aircraft, military vehicles, unmanned aerial vehicles (UAVs), and other defense systems, as they ensure the engines operate at their best even in challenging environments and during critical missions.

Why Engine SACOCs?

Engine SACOC heat exchangers offer several advantages over traditional brick coolers when it comes to reducing drag, achieving fuel savings, and optimizing space within the engine compartment. Let's explore the benefits and applications of engine surface coolers and how they excel in delivering exceptional solutions.

Reduced Drag: Engine SACOCs are typically designed to have a streamlined profile that integrates more smoothly with the aircraft's overall shape. This reduces aerodynamic drag compared to traditional brick coolers, which tend to have a bulkier and less streamlined design. Reduced drag leads to improved fuel efficiency and overall aircraft performance.

Improved Fuel Efficiency: The streamlined design of surface coolers helps minimize the disruption of airflow around the engine cowling. This leads to lower fuel consumption as the aircraft requires less energy to maintain its desired speed and altitude. Over time, the fuel savings can contribute to significant cost savings for airlines and operators.

Optimized Engine Compartment Space: Placing surface coolers on the engine cowling or other exterior surfaces frees up valuable space within the engine compartment. This extra space can be utilized for other critical components, such as sensors, actuators, or exhaust systems. This optimization of internal space can lead to more efficient packaging of various engine systems, potentially improving maintenance accessibility and reducing overall weight.

Enhanced Engine Cooling System: Engine surface coolers can be positioned in areas that receive direct airflow, taking advantage of the high-speed incoming air to efficiently dissipate heat. This can result in improved engine cooling efficiency compared to traditional brick coolers that may be tucked away within the engine compartment and ex

posed to less direct airflow.

Simplified Maintenance: Placing coolers on the exterior of the engine cowling can make them more accessible for maintenance and inspection. This can lead to quicker and easier maintenance procedures, reducing downtime and improving overall aircraft operational efficiency.

Adaptability to New Engine Designs: As aircraft and engine designs evolve, surface coolers can be more easily integrated into new configurations. Their modular and external nature makes it relatively straightforward to adapt them to different engine sizes, shapes, and layouts without requiring major modifications to the core engine structure.

Weight Reduction: Traditional brick coolers can add weight to the engine and the aircraft as a whole. Surface coolers, if designed using lightweight materials and efficient construction methods, can help reduce overall weight, leading to improved fuel efficiency and payload capacity.

Improved Engine Heat Management: Placing coolers on the engine cowling or external surfaces can help isolate heat from critical internal components, contributing to better heat management and potentially extending the lifespan of engine parts.

Precision engineered aerospace cooling technology solutions like AMETEK Hughes-Treitler

It's worth noting that while surface coolers offer these advantages, their design and integration must consider factors such as the need for proper aerodynamics, protection against environmental elements, and potential impact on aircraft maintenance procedures. Engineers need to carefully balance these considerations to ensure that the benefits of surface coolers are effectively realized while maintaining the safety and performance of the aircraft.

Tailored Solutions for Aerospace and Defense

Each aerospace and defense application is unique, and engine surface coolers need to be customized to meet specific requirements. Custom solutions must be manufactured with extensive experience, and meticulously designed to cater to the rigorous demands of the industry. From military aircraft to unmanned aerial vehicles (UAVs) and defense systems, these solutions are engineered to withstand harsh environments, vibration, and high-temperature differentials.

The Importance of Superior Design and Quality

Engine surface coolers undergo rigorous testing and adhere to stringent industry standards, ensuring optimal performance and reliability in even the most challenging applications. By prioritizing quality, surface engine coolers can deliver exceptional performance, minimize the risk of overheating, and contribute to the overall efficiency and reliability of engines in aerospace and defense applications. They provide the assurance that critical systems will function optimally, ensuring the safety and success of missions and operations.

The AMETEK Hughes-Treitler advantage

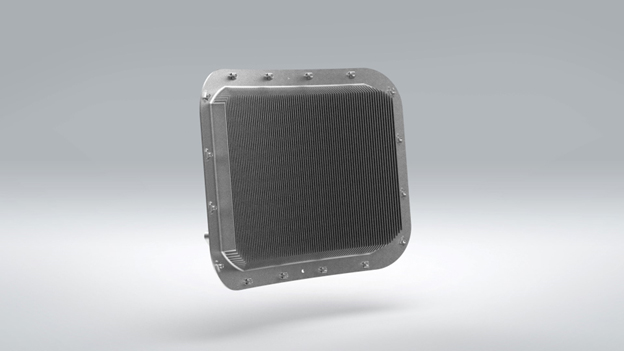

At AMETEK Hughes-Treitler, we specialize in delivering custom-designed thermal solutions. As showcased by this custom engine surface cooler made for Rolls-Royce, we have the expertise to create innovative and high-performance solutions that meet your unique requirements. With a weight of 9.75 lbs. (4.42 kg), this engine surface cooler offers optimal performance and efficiency. It is oil cooled with MIL-L-23699 oil, ensuring reliable operation even in demanding conditions. With an oil flow rate of 8.0 gpm (30.28 lpm) and an inlet oil temperature of 240OF (116OC), this cooler efficiently dissipates heat while maintaining a pressure drop (DP) of 12 psi. Constructed with high-quality aluminum, this cooler is built to withstand the rigorous demands of aerospace applications. Its remarkable heat rejection capability of 82,800 BTU/hr. makes it an ideal choice for Rolls-Royce engines, providing superior cooling and enhancing overall performance.

The AMETEK Hughes-Treitler advantage lies in our ability to provide innovative solutions that address thermal performance challenges while reducing weight and improving overall efficiency. Contact our experts today to see how our innovations can benefit your next project.